Our Services

Ask With Experts

Our Client care managers are on call 24/7 to answer your questions representative or submit a business inquiry online.

+971 50 127 2160

Operation & Maintenance

Services We Provide

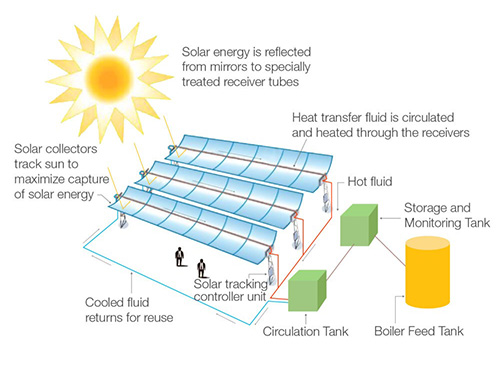

For Solar Plants

Solar Plants maintenance can help maximize uptime and extend the life of the plant. The delivery of solar power without any disruption maintains the stream of economic value generated by each kilowatt hour of production, and proper service is a critical component to ensuring optimal performance while minimizing the risks of downtime. A well-maintained solar installation can actually perform 10 to 30% better than one that is not. But installing solar arrays are just the beginning. Without proper operation and maintenance, system components could be void of all warranties.

DOMAGUA Energia has a dedicated team of field-service engineers and technicians who will actively oversee the quality and performance of a solar project with effective maintenance. Typically, this will involve signing maintenance with the agreement to meet your specific goals and needs.

The following services are included in a Domagua Solar Plant Maintenance contract:

Site visits: Our team will come on site to inspect your installation and analyze whether it is producing the amount of power it has promised.

Cleaning: On average, regular solar array cleaning will increase annual solar energy production by 5 to 10% in climates with a dry season.

Electrical system checks: We shall check the electrical systems to make sure they are performing properly — and make corrections if they are not.

Solar Inverter preventative maintenance: Checks and corrections for your solar inverters will be done by experts

Additional Services Include:

Audit of energy production

• Evaluation of network voltage and frequency

• Inventory and spare parts management

• Environment conditions control

• Coordinate warranty repairs and regular service checks

Domagua Crew use software and monitoring services to proactively pinpoint faults in a system and assess the financial benefits of service and maintenance by weighing repair costs against the value of energy lost. For instance, our software can monitor systems in real time and even archive data for a minimum of 20 years. This allows system owners and plant managers to make intelligent decisions regarding O&M expenditures. This goes along with a trend toward predictive maintenance, rather than reactive. Annual or biannual diagnostics and preventive maintenance address any potentials issues and ensure the system will continue to perform as designed. Out of reactive, preventive, and predictive maintenance, predictive offers the best balance of failure and maintenance costs.

• Satisfaction Value For Money Solution

• Vertical Axis Wind Turbine

• Horizontal Axis Wind Turbine

• Wind Mills

• Capicola ground round venison

Product Guide

Residential: Buildings and Villas

Commercial: Warehouses and Industrial Buildings